|

|

FKC

Screw Prewss 는 제지, 식품, 화학 업계를 처음으로 그 외 여러

분야에 광범위하게 이용 가능한 기계식

탈수 장치로써 1958년부터

생산되어져 왔습니다.

구체적으로는

, 단침오니나 활성 오니의 각각의 단체, 혹은 혼합한 상태로의 오니,

PULP나 리젝트, ABS , 쥬스,

두부나 어묵 등 여러 업종 업계에

사용되어져 왔습니다.

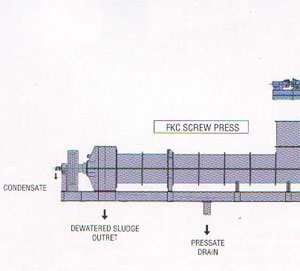

Screw

Press의 기능은, 고체와액체의 혼합물을 경사져 있는 Screw에 투입하여

출구부에 갈수록 감소하는 Screw와

Screen 의 용적에 의한

탈수를 행하여 탈수된 액체는 Screw 주위에 취부되어져 구멍이 나있는

Screen으로부터

배출되어 집니다.

간단한

구조로 되어 있지만 주로 Screw Design에 주력하여 대구경에 의한

저 회전 운전에 의하여 어떻게 하면

무리 없이 Screw 전체로

탈수를 할것인가가 FKC SCREW PRESS의 기본원리입니다.

|

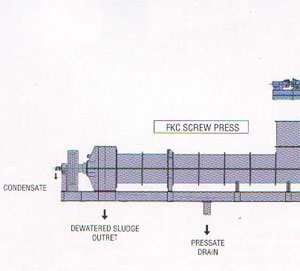

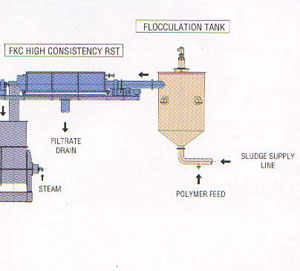

Process

Flow Diagram Example (Pulp & Paper Application)

|

|

|

|

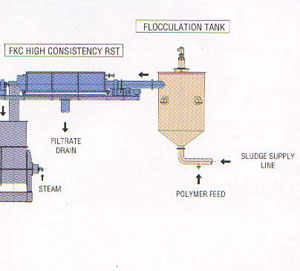

A typical

FKC sludge dewatering system utilizes a flocculation tank,

rotary screen thickener, and screw press.

Sludge is

fed to the system from a sludge blend tank or clarifler.

Ploymer, when required, is added to the sludge just prior

to the flocculation tank. From the flocculation tank the

conditioned sludge flows by gravity into the high consistency

rotary screen thickener (HC-RST) where the dewatering process

begins. The thickened sludge is gravity fed from the

HC-RST into the srew press where final dewatering occurs.

일반적으로 반응조, Rotary Screen, Screw Press

가 상기와 같이 설치되어 오니 탈수를 행합니다.

반응조로부터

응집된 오니는 HC-RST로 공급되어 유이수를 제거한후 Screw

Press로 투입되어 탈수합니다.

|

|

|

|

*stock

thickening:

Chemical

Pulp, Mechanical and Recyled Pulp

*Knots and Rejects:

Pulp Mill knot and shives, screen

Rejects cleaner ejects

*오

니 : 단침, 응침, 부상,

잉여오니, 3차처리오니 |

|

|

|

- Chenmical

cmc, 의약품, 합성고무, 합성수지, 친수

폴리머, 나프탈렌, 고무계 접착제, 컬러 필름 유액, 화학공장에서의

폐수처리,

라텍스 배수, 젤라틴 배수, 페라이트 오니, 도금배수오니.

|

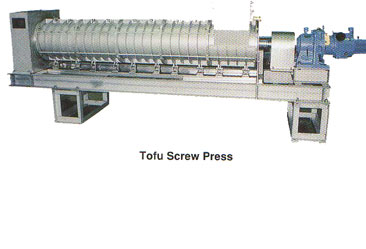

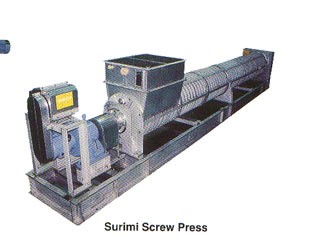

- Food

다짐, 어육, 곡물섬유, 야채, 과실쥬스,

펙틴, 맥주 , 위스키의 추출 찌꺼기, 커피 추출 찌꺼기, 차

추출 찌꺼기,

오렌지 껍질,두유, 두부, 비치, 재정유,

도살장의 쓰레기 배수, 기타 폐수 오니

|

|

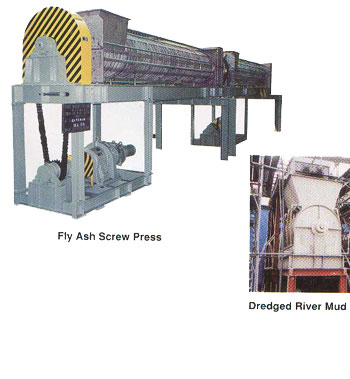

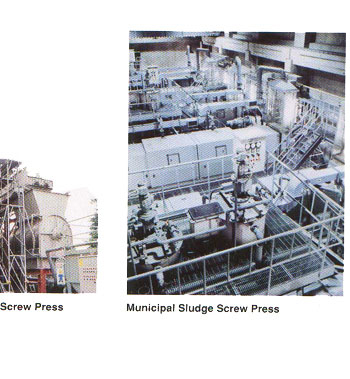

- Miscellaneous

도시하수, 재날림, 호수하천의 준설진흙,

염색오니, 제혁공정에서 생긴 오니, 기타 여러 산업에 의한

배수 오니

|

|

|

|

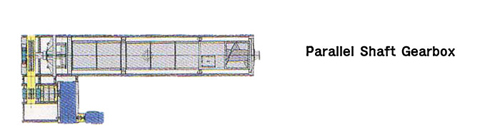

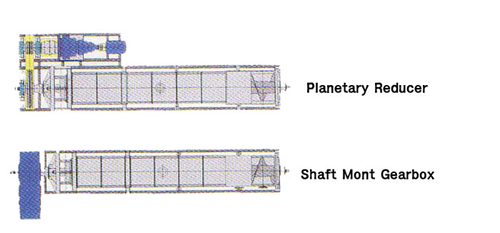

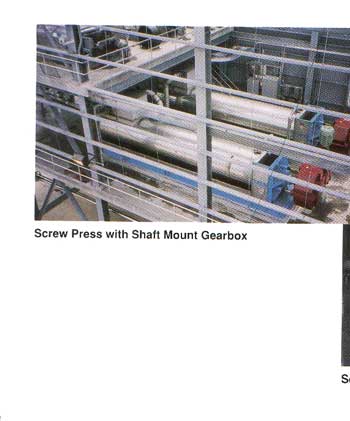

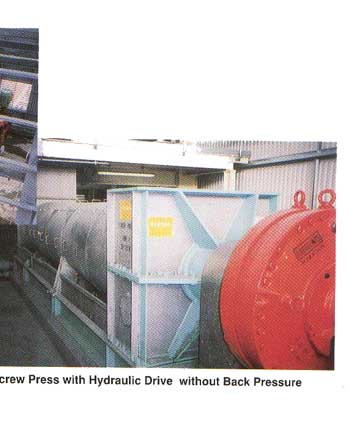

*Parallel

Shaft Gearbox

*Cyclo Reducer

*Hydraulic drive

*Planetary

Reducer

*Shaft Mount

Gearbox

|

대구경

screw에서의 저속운전으로 공급조건의

변화에도 유연한 대응이 가능하여

maintenance도 용이합니다.

|

.통상

증기로 screw를 가열하는 것으로 screw

press의 능력 이 향상합니다. 또한

열이 screw에 접촉하고 잇는 부분의

마 찰저항을 감소시키기 때문에 필요동력을

감소시켜(모터 마력 을 작게 해서)

screw의 마모가 작습니다

|

접액부는

Stainless steel material를 사용하는

것이 표준입 니다. SUS-304, 316 그리고

316L 중에서 선택이 가능합니다.

|

|

|

|

|

|

|

|

|

1. Applicate information

|

탈주

대상물의 성질과 상태 및 요구사양을 알려 주십시요.

(종류-대상물,

공정, 현재 탈수기 종류, 입구농도, 희망 CAKE함수율 등)

|

2.Conference with customer

|

위 내용에 기초하여 전문

Engineer가 고객을 방문,상의하여 고객의 요구사항에 맞는

model 및 사양을 선정하고 설계합니다.

|

3. Model sellection &

Design

|

고객의 요구와 FKC의

Know-how를 가미하여 최적의 Screw Press를 설계하여

고객에게

지원합니다.

|

4. Running Test and A/S

|

Screw press가

완성되면 설치및 시운전까지 고객의 요구에 맞도록 조정하여

사용하기까지 Engineering 및 A/S를 지원합니다.

|

|

|

|

|

|

전남 여수시 한려동 1238번지

Tel: (061) 691- 6741

Fax: (061) 664 - 0313 |

|